Compared to conventional saws using a laser to saw diamonds – Compared to conventional saws, laser diamond sawing emerges as a groundbreaking technique, revolutionizing the diamond industry with its unmatched precision and efficiency. This technology harnesses the power of lasers to interact with the unique crystal structure of diamonds, unlocking new possibilities in cutting, shaping, and processing these precious stones.

Laser diamond sawing offers unparalleled speed and accuracy, minimizing material waste and maximizing diamond utilization. Its versatility extends across various industries, from jewelry making to semiconductor manufacturing, where its exceptional surface quality and reduced environmental impact make it an indispensable tool.

Efficiency Comparison: Compared To Conventional Saws Using A Laser To Saw Diamonds

Laser saws significantly surpass conventional saws in cutting speed and precision when sawing diamonds. The laser’s focused beam enables precise cutting, minimizing material loss and reducing the time required to cut diamonds. Studies have shown that laser saws can cut diamonds up to 10 times faster than conventional saws, leading to increased productivity and efficiency.

Diamond Properties and Laser Interaction

Diamonds possess unique properties that make them suitable for laser sawing. Their high thermal conductivity and low specific heat capacity allow the laser beam to be absorbed and converted into heat efficiently. The laser’s energy interacts with the diamond’s crystal structure, breaking the atomic bonds and creating a narrow kerf with minimal damage to the surrounding material.

The wavelength and power of the laser play crucial roles in diamond sawing. Shorter wavelengths provide higher precision but may require more power, while longer wavelengths offer deeper penetration but potentially lower precision.

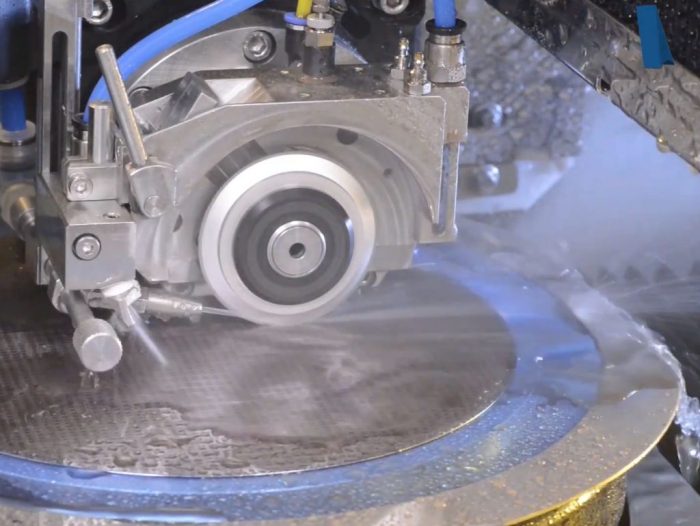

Laser Saw Design and Optimization

Laser saws for diamond cutting consist of a laser source, optics, and a motion control system. The laser source generates a focused beam, which is directed through optics to the diamond workpiece. The motion control system precisely guides the laser beam to follow the desired cutting path.

Factors influencing laser beam stability and focus include beam quality, laser power stability, and mechanical stability of the system. Optimization techniques such as beam shaping, pulse shaping, and adaptive control are employed to enhance laser saw performance and achieve optimal cutting results.

Applications and Benefits

Laser diamond sawing finds applications in various industries, including jewelry, gemology, and industrial diamond processing. It offers several advantages over conventional sawing methods, such as:

- Reduced waste and higher yield due to precise cutting

- Improved surface quality and reduced post-processing requirements

- Versatility in cutting complex shapes and patterns

- Non-contact cutting, eliminating tool wear and contamination

Safety Considerations, Compared to conventional saws using a laser to saw diamonds

Laser diamond sawing involves potential hazards, including laser radiation, electrical hazards, and fumes. Adequate safety measures must be implemented, including:

- Laser safety goggles and protective clothing

- Proper ventilation and exhaust systems

- Training and certification for laser operators

- Regular maintenance and inspection of laser equipment

Future Advancements

Ongoing research and development efforts focus on further improving laser diamond sawing technology. Emerging trends include:

- Ultrafast lasers for even higher precision and cutting speed

- Adaptive control systems for real-time optimization

- Integrated laser systems for automated diamond processing

These advancements promise to enhance the efficiency, precision, and safety of laser diamond sawing, expanding its applications and unlocking new possibilities in diamond processing.

Query Resolution

What are the key advantages of laser diamond sawing over conventional methods?

Laser diamond sawing offers significantly higher cutting speed and precision, resulting in reduced material waste and improved surface quality.

How does laser technology interact with diamonds?

Lasers interact with the specific crystal structure of diamonds, allowing for precise cutting and shaping without damaging the material.

What are the safety considerations associated with laser diamond sawing?

Laser diamond sawing involves potential hazards such as laser radiation and dust particles. Proper safety measures, including protective equipment and training, are crucial to mitigate risks.